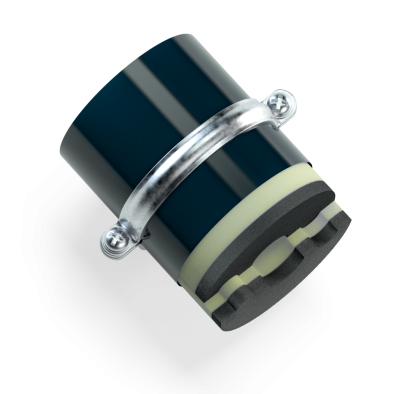

In refrigeration / industrial refrigeration systems – fixing, vapour diffusion proofing

In refrigeration / industrial refrigeration systems – fixing, vapour diffusion proofing

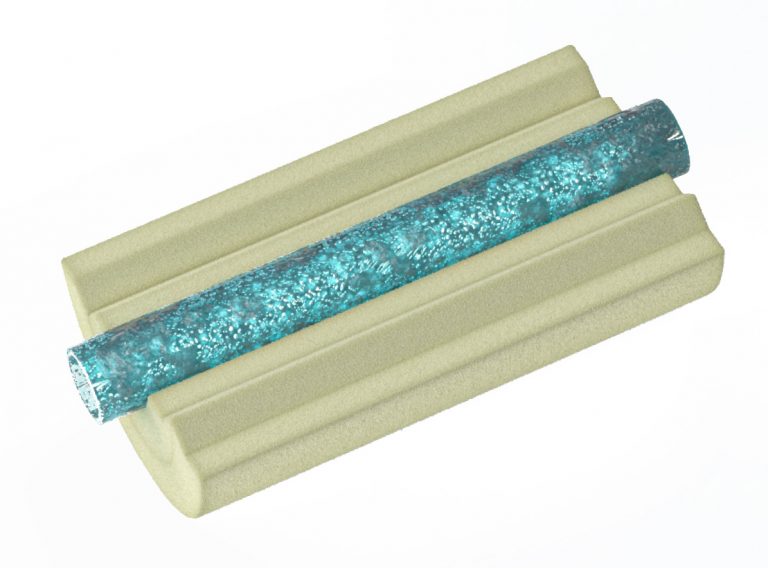

With or without clamp

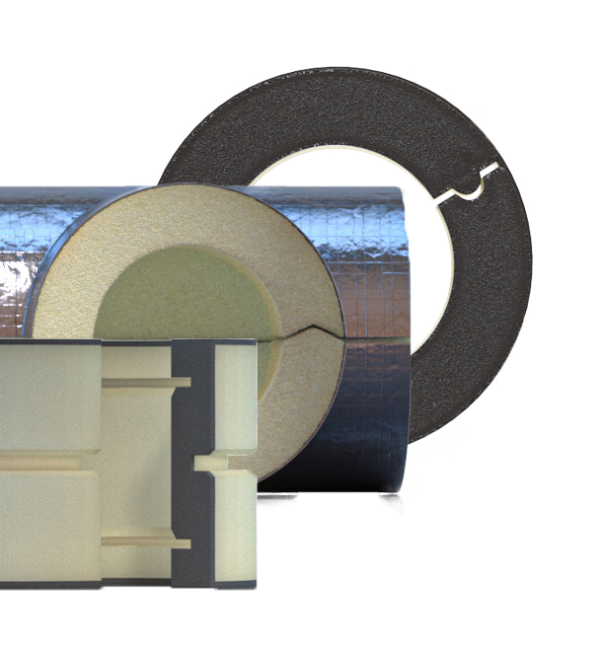

Depending on the pipe thickness, the 2, 3 or more components of the high load-bearing interlocking pipe clamp insert segment are mechanically strong, and provide adequate thermal insulation

for any pipe size. The pipe clamp insert consists of two semicircular parts made of polyurethane foam. The two half rings are covered with ALU tape, the ends of which are self-adhesive and covered with a protective film. The pipe clamp insert segment and the ALU coating form a strong water and vapour barrier layer. The finished pipe clamp insert has good heat retention properties, making it ideal for the thermal insulation of pipes (both cooling and heating). Our pipe clamp inserts are mainly used in the construction and petrochemical industries where a high degree of insulation is required. The inner diameter of the pipe clamp insert is the same as the outer diameter of the pipe on which it will be installed. The outer diameter of the product is the same as the outer diameter of the pipe insulated with pipe shells or plates, and matches the inner diameter of the supporting metal clamp.

| Property | Value |

|---|---|

| Temperature range | -45 and 105ºC between |

| Processing temperature | above 10ºC |

| Shelf life | 1 year (above 10ºC) |

| Vapour diffusion resistance | μ > 7000 |

| Width | inner ø <114 mm - 50mm inner ø >= 114 mm - 100mm |

| Colour | black |

| Fire resistance | B2 (according to DIN 4102) |

| Tolerance | inner +/-0.5 mm; outer +/- 1 mm |

| PU foam substrate | 80/120/145 kg/m³ |

| Description | Type | Support Inner Diameter (inch) | Support Wall Thickness (inch) | Support Length (inch) | Support Outside Diameter (inch) |

|---|---|---|---|---|---|

| 0.84 inch ID | 1/2 inch wall | 0,866 | 0,512 | 2,0 | 1,9 |

| 1.10 inch ID | 1/2 inch wall | 1,1 | 0,5125 | 2,0 | 2,1 |

| 1.66 inch ID | 1/2 inch wall | 1,66 | 0,53 | 2,0 | 2,7 |

| 1.875 inch ID | 1/2 inch wall | 1,89 | 0,53 | 2,0 | 2,9 |

| 2.35 inch ID | 1/2 inch wall | 2,35 | 0,55 | 2,0 | 3,5 |

| 2.5 inch ID | 3/4 inch wall | 2,51 | 0,76 | 2,0 | 4,0 |

| 3 inch ID | 3/4 inch wall | 2,99 | 0,76 | 2,0 | 4,5 |

| 3.5 inch ID | 3/4 inch wall | 3,50 | 0,76 | 2,0 | 5,0 |

| 4.25 inch ID | 3/4 inch wall | 4,25 | 0,80 | 4,0 | 5,9 |

| 4.50 inch ID | 3/4 inch wall | 4,50 | 0,80 | 4,0 | 6,1 |

| 5.25 inch ID | 3/4 inch wall | 5,24 | 0,80 | 4,0 | 6,8 |

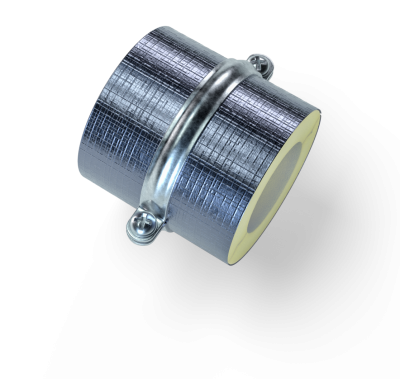

Cooling/heating systems, fastening technology

Polyurethane foam, ALU coating

With or without clamp

Depending on the pipe thickness, the 2, 3 or more components of the high load-bearing interlocking pipe clamp insert segment are mechanically strong, and provide adequate thermal insulation for any pipe size. The pipe clamp insert consists of two semicircular parts made of polyurethane foam. The two half rings are covered with ALU tape, the ends of which are self-adhesive and covered with a protective film. The pipe clamp insert segment and the ALU coating form a strong water and vapour barrier layer. The finished pipe clamp insert has good heat retention properties, making it ideal for the thermal insulation of pipes (both cooling and heating). Our pipe clamp inserts are mainly used in the construction and petrochemical industries where a high degree of insulation is required. The inner diameter of the pipe clamp insert is the same as the outer diameter of the pipe on which it will be installed. The outer diameter of the product is the same as the outer diameter of the pipe insulated with pipe shells or plates, and matches the inner diameter of the supporting metal clamp.

| Property | Value |

|---|---|

| Temperature range | between -45 and 120ºC |

| Processing temperature | above 10ºC |

| Shelf life | 1 year (above 10ºC) |

| Vapour diffusion resistance | μ > 7000 |

| Width | inner ø <114 mm - 75mm inner ø >= 114 mm - 100mm |

| Colour | grey |

| Fire resistance | B2 (according to DIN 4102) |

| Tolerance | inner +/-0,5 mm; outer +/- 1 mm |

| PU foam substrate | 80/120/145 kg/m³ |

| Description | Type | Support Inner Diameter (inch) | Support Wall Thickness (inch) | Support Length (inch) | Support Outside Diameter (inch) |

|---|---|---|---|---|---|

| 0.84 inch ID | 1/2 inch wall | 0,866 | 0,512 | 2,0 | 1,9 |

| 1.10 inch ID | 1/2 inch wall | 1,1 | 0,5125 | 2,0 | 2,1 |

| 1.66 inch ID | 1/2 inch wall | 1,66 | 0,53 | 2,0 | 2,7 |

| 1.875 inch ID | 1/2 inch wall | 1,89 | 0,53 | 2,0 | 2,9 |

| 2.35 inch ID | 1/2 inch wall | 2,35 | 0,55 | 2,0 | 3,5 |

| 2.5 inch ID | 3/4 inch wall | 2,51 | 0,76 | 2,0 | 4,0 |

| 3 inch ID | 3/4 inch wall | 2,99 | 0,76 | 2,0 | 4,5 |

| 3.5 inch ID | 3/4 inch wall | 3,50 | 0,76 | 2,0 | 5,0 |

| 4.25 inch ID | 3/4 inch wall | 4,25 | 0,80 | 4,0 | 5,9 |

| 4.50 inch ID | 3/4 inch wall | 4,50 | 0,80 | 4,0 | 6,1 |

| 5.25 inch ID | 3/4 inch wall | 5,24 | 0,80 | 4,0 | 6,8 |

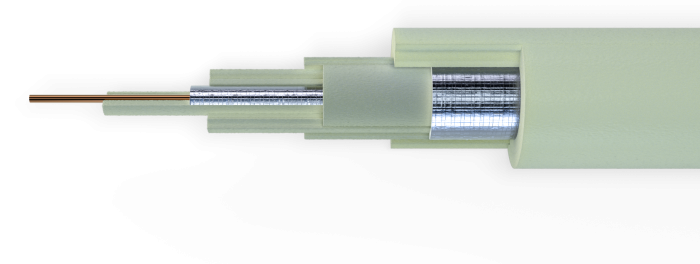

As insulating material for cooling/heating systems, cold/hot process systems.

Polyurethane foam, Alu and Al-clad.

Depending on the pipe thickness, 2, 3 or more interlocking segments of high load-bearing pipe shell segments are mechanically strong, and provide adequate thermal insulation for any pipe size. The interlocking pipe shells are originally laminated with aluminium foil, but can also be ordered without it. The finished pipe shell has good heat retention properties, the polyurethane foam and the

ALU coating prevents the formation of condensation between the pipe and the shell. Considering the advantages of the base material, their application can effectively reduce heat loss.

| Property | Value |

|---|---|

| Temperature range | between -45 and 105 ºC |

| Processing temperature | above 10 ºC |

| Shelf life | 1 year (above 10 ºC) |

| Vapourdiffusion resistance | 0.03g/qm/24 according to DIN 53122 |

| Length | 100 cm |

| Colour | black |

| Fire resistance | B2 (according to DIN 4102) |

| Tolerance | inner +/-0.5 mm; outer +/- 1 mm |

| PU foam substrate | 32/80/120 kg/m³ |

Raw density EN 1602: 38 – 42 kg/m³,

Thermal conductivity at application temperature 10 °C EN 14308: [0.027] [0.026] [0.025] W/(m∙K)

For short periods up to +250°C

Raw density (EN 1602): 37 – 42 kg/m³

Monitored limit (fresh value) at 10 °C mean temperature EN 12667: 0.021 W/(m∙K)

At 10 °C application temperature EN 13165 / EN14308: [0.027] [0.026] [0.025] W/(m∙K)

Designation (EU) [EN 13165] PU-EN 13165-T2-DS(70,90) 3-DS(-20,-) 2-CS(10\Y) 250-TR150

Designation (EU) [EN 14308] PU-EN 13165-T2-DS(70,90) 3-DS(-20,-) 2-CS(10\Y) 250-TR150

Contact us for orders and more information!